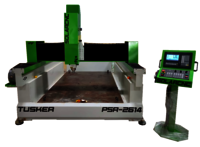

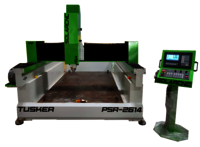

CNC Pattern Router Machine

Product Details:

- Product Type CNC PATTERN ROUTER

- Material Aluminum

- Type Other

- Weight (kg) 4500 Kilograms (kg)

- Computerized Yes

- Automatic Yes

- PLC Control No

- Click to View more

CNC Pattern Router Machine Price And Quantity

- 3500000.00 INR/Piece

- 1 Piece

CNC Pattern Router Machine Product Specifications

- No

- Other

- 1 year

- Aluminum

- 4500 Kilograms (kg)

- Electric

- CNC PATTERN ROUTER

- Green

- Yes

- 3500*2500

- Yes

- 4000*3200*3500 Millimeter (mm)

- 8000 to 24000

- AC Motor

- 12 Horsepower (HP)

- No

- High

- 415 Volt (V)

CNC Pattern Router Machine Trade Information

- Cash on Delivery (COD) Letter of Credit (L/C)

- 1 Piece Per Month

- 60 Days

Product Description

CNC pattern making machine is a computer-controlled system designed specifically for creating patterns and molds used in various industries, such as woodworking, foundries, and prototyping. It utilizes computer numerical control (CNC) technology to precisely carve, mill, or cut patterns from a variety of materials, including wood, foam, plastic, and composites. The CNC system allows for highly accurate and repeatable pattern production, enabling faster and more efficient manufacturing processes.

FAQ (Frequently Asked Questions):

Q: What is a CNC pattern making machine?

A: A CNC pattern making machine is a computer-controlled system that automates the process of creating patterns and molds. It utilizes CNC technology to accurately shape and carve patterns from various materials, providing a precise and efficient solution for pattern making in different industries.

Q: How does a CNC pattern making machine work?

A: A CNC pattern making machine works by following pre-programmed instructions to control the movement of cutting tools or carving heads. The machine's computerized control system interprets the design data and precisely positions the cutting tools to shape the material into the desired pattern. This allows for consistent and accurate reproduction of patterns with high levels of detail and complexity.

Q: What types of materials can be used with a CNC pattern making machine?

A: CNC pattern making machines can work with a wide range of materials, including wood, foam, plastic, composites, and even certain metals. The choice of material depends on the specific application and the desired characteristics of the pattern or mold.

Q: What are the advantages of using a CNC pattern making machine?

A: Using a CNC pattern making machine offers several advantages. It provides high precision and accuracy in pattern production, ensuring consistency and repeatability. The machine can handle intricate and complex designs that would be challenging or time-consuming to create manually. CNC pattern making machines also enable faster production cycles, improved efficiency, and reduced material waste compared to traditional manual methods.

Q: What industries can benefit from a CNC pattern making machine?

A: CNC pattern making machines are valuable in various industries that require the production of patterns and molds. They are commonly used in woodworking, foundries, prototyping, and manufacturing sectors. These machines cater to applications such as furniture making, architectural moldings, automotive parts prototyping, and casting pattern production.CNC pattern making machine is a computer-controlled system designed specifically for creating patterns and molds used in various industries, such as woodworking, foundries, and prototyping. It utilizes computer numerical control (CNC) technology to precisely carve, mill, or cut patterns from a variety of materials, including wood, foam, plastic, and composites. The CNC system allows for highly accurate and repeatable pattern production, enabling faster and more efficient manufacturing processes.

FAQ (Frequently Asked Questions):

Q: What is a CNC pattern making machine?

A: A CNC pattern making machine is a computer-controlled system that automates the process of creating patterns and molds. It utilizes CNC technology to accurately shape and carve patterns from various materials, providing a precise and efficient solution for pattern making in different industries.

Q: How does a CNC pattern making machine work?

A: A CNC pattern making machine works by following pre-programmed instructions to control the movement of cutting tools or carving heads. The machine's computerized control system interprets the design data and precisely positions the cutting tools to shape the material into the desired pattern. This allows for consistent and accurate reproduction of patterns with high levels of detail and complexity.

Q: What types of materials can be used with a CNC pattern making machine?

A: CNC pattern making machines can work with a wide range of materials, including wood, foam, plastic, composites, and even certain metals. The choice of material depends on the specific application and the desired characteristics of the pattern or mold.

Q: What are the advantages of using a CNC pattern making machine?

A: Using a CNC pattern making machine offers several advantages. It provides high precision and accuracy in pattern production, ensuring consistency and repeatability. The machine can handle intricate and complex designs that would be challenging or time-consuming to create manually. CNC pattern making machines also enable faster production cycles, improved efficiency, and reduced material waste compared to traditional manual methods.

Q: What industries can benefit from a CNC pattern making machine?

A: CNC pattern making machines are valuable in various industries that require the production of patterns and molds. They are commonly used in woodworking, foundries, prototyping, and manufacturing sectors. These machines cater to applications such as furniture making, architectural moldings, automotive parts prototyping, and casting pattern production.CNC pattern making machine is a computer-controlled system designed specifically for creating patterns and molds used in various industries, such as woodworking, foundries, and prototyping. It utilizes computer numerical control (CNC) technology to precisely carve, mill, or cut patterns from a variety of materials, including wood, foam, plastic, and composites. The CNC system allows for highly accurate and repeatable pattern production, enabling faster and more efficient manufacturing processes.

FAQ (Frequently Asked Questions):

Q: What is a CNC pattern making machine?

A: A CNC pattern making machine is a computer-controlled system that automates the process of creating patterns and molds. It utilizes CNC technology to accurately shape and carve patterns from various materials, providing a precise and efficient solution for pattern making in different industries.

Q: How does a CNC pattern making machine work?

A: A CNC pattern making machine works by following pre-programmed instructions to control the movement of cutting tools or carving heads. The machine's computerized control system interprets the design data and precisely positions the cutting tools to shape the material into the desired pattern. This allows for consistent and accurate reproduction of patterns with high levels of detail and complexity.

Q: What types of materials can be used with a CNC pattern making machine?

A: CNC pattern making machines can work with a wide range of materials, including wood, foam, plastic, composites, and even certain metals. The choice of material depends on the specific application and the desired characteristics of the pattern or mold.

Q: What are the advantages of using a CNC pattern making machine?

A: Using a CNC pattern making machine offers several advantages. It provides high precision and accuracy in pattern production, ensuring consistency and repeatability. The machine can handle intricate and complex designs that would be challenging or time-consuming to create manually. CNC pattern making machines also enable faster production cycles, improved efficiency, and reduced material waste compared to traditional manual methods.

Q: What industries can benefit from a CNC pattern making machine?

A: CNC pattern making machines are valuable in various industries that require the production of patterns and molds. They are commonly used in woodworking, foundries, prototyping, and manufacturing sectors. These machines cater to applications such as furniture making, architectural moldings, automotive parts prototyping, and casting pattern production.CNC pattern making machine is a computer-controlled system designed specifically for creating patterns and molds used in various industries, such as woodworking, foundries, and prototyping. It utilizes computer numerical control (CNC) technology to precisely carve, mill, or cut patterns from a variety of materials, including wood, foam, plastic, and composites. The CNC system allows for highly accurate and repeatable pattern production, enabling faster and more efficient manufacturing processes.

FAQ (Frequently Asked Questions):

Q: What is a CNC pattern making machine?

A: A CNC pattern making machine is a computer-controlled system that automates the process of creating patterns and molds. It utilizes CNC technology to accurately shape and carve patterns from various materials, providing a precise and efficient solution for pattern making in different industries.

Q: How does a CNC pattern making machine work?

A: A CNC pattern making machine works by following pre-programmed instructions to control the movement of cutting tools or carving heads. The machine's computerized control system interprets the design data and precisely positions the cutting tools to shape the material into the desired pattern. This allows for consistent and accurate reproduction of patterns with high levels of detail and complexity.

Q: What types of materials can be used with a CNC pattern making machine?

A: CNC pattern making machines can work with a wide range of materials, including wood, foam, plastic, composites, and even certain metals. The choice of material depends on the specific application and the desired characteristics of the pattern or mold.

Q: What are the advantages of using a CNC pattern making machine?

A: Using a CNC pattern making machine offers several advantages. It provides high precision and accuracy in pattern production, ensuring consistency and repeatability. The machine can handle intricate and complex designs that would be challenging or time-consuming to create manually. CNC pattern making machines also enable faster production cycles, improved efficiency, and reduced material waste compared to traditional manual methods.

Q: What industries can benefit from a CNC pattern making machine?

A: CNC pattern making machines are valuable in various industries that require the production of patterns and molds. They are commonly used in woodworking, foundries, prototyping, and manufacturing sectors. These machines cater to applications such as furniture making, architectural moldings, automotive parts prototyping, and casting pattern production.CNC pattern making machine is a computer-controlled system designed specifically for creating patterns and molds used in various industries, such as woodworking, foundries, and prototyping. It utilizes computer numerical control (CNC) technology to precisely carve, mill, or cut patterns from a variety of materials, including wood, foam, plastic, and composites. The CNC system allows for highly accurate and repeatable pattern production, enabling faster and more efficient manufacturing processes.

FAQ (Frequently Asked Questions):

Q: What is a CNC pattern making machine?

A: A CNC pattern making machine is a computer-controlled system that automates the process of creating patterns and molds. It utilizes CNC technology to accurately shape and carve patterns from various materials, providing a precise and efficient solution for pattern making in different industries.

Q: How does a CNC pattern making machine work?

A: A CNC pattern making machine works by following pre-programmed instructions to control the movement of cutting tools or carving heads. The machine's computerized control system interprets the design data and precisely positions the cutting tools to shape the material into the desired pattern. This allows for consistent and accurate reproduction of patterns with high levels of detail and complexity.

Q: What types of materials can be used with a CNC pattern making machine?

A: CNC pattern making machines can work with a wide range of materials, including wood, foam, plastic, composites, and even certain metals. The choice of material depends on the specific application and the desired characteristics of the pattern or mold.

Q: What are the advantages of using a CNC pattern making machine?

A: Using a CNC pattern making machine offers several advantages. It provides high precision and accuracy in pattern production, ensuring consistency and repeatability. The machine can handle intricate and complex designs that would be challenging or time-consuming to create manually. CNC pattern making machines also enable faster production cycles, improved efficiency, and reduced material waste compared to traditional manual methods.

Q: What industries can benefit from a CNC pattern making machine?

A: CNC pattern making machines are valuable in various industries that require the production of patterns and molds. They are commonly used in woodworking, foundries, prototyping, and manufacturing sectors. These machines cater to applications such as furniture making, architectural moldings, automotive parts prototyping, and casting pattern production.

Other Products in 'CNC Router And Wood Carving Machine' category

Mobile :+91-9998063663

Saurabh Thakkar (Partner)

Mobile :+91-9824234266

|

SOLAR CNC AUTOMATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese