- Home Page

- Company Profile

-

Our Products

- CNC Router And Wood Carving Machine

- CNC Milling Machine

- CNC Plasma Cutting Machine

- Plasma Cutting Machine

- Plasma Cutting CNC

- CNC Plasma Cutting Machine

- CNC Profile Cutting Machine

- CNC Gantry Type Plasma Cutting Machine

- Flash Cut CNC Oxy Fule and Plasma Cutting Machine

- Gantry CNC Plasma Flame Cutting Machine

- CNC Plasma Flame Cutting

- Portable Cnc Plasma Cutting Machine

- Table Top CNC Plasma Cutting Machine

- Portable Oxyfuel Cutting Machine

- Portable Cnc Flame Plasma Cutting Machine

- CNC Engraving Machine

- CNC Trainer Machines

- Special Purpose Machines

- CNC Lathe Machines

- Stone Engraving Machine

- Vertical Roll Storage Carousel

- Welding Robot

- CNC Machines

- CNC Router Machines

- Cnc Metal Engraving Machine

- 5 Axis CNC Router Machine

- CNC 3 Axis Stepper Router Machine

- CNC Router Machine SR-E 2614

- Double Spindle CNC Router Machine

- Double Head Stone CNC Router

- Wood Pattern Making Cnc Router Machine

- Industrial CNC Engraving Machine

- Robot Welding Machines

- CNC 3 Axis Servo Router Machine

- 3 Axis CNC Router Machine manufacturer in Gujarat

- CNC Pattern Router Machine

- Welding Fixtures

- Contact Us

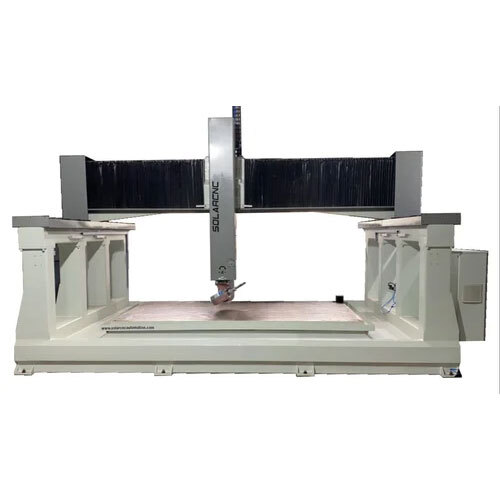

5 Axis CNC Router Machine

5000000.0 INR/Unit

Product Details:

- Product Type 5 Axis CNC Router Machine

- General Use Industrial

- Material Other

- Weight (kg) 6000 Kilograms (kg)

- Computerized No

- Automatic Yes

- Power Source Electric

- Click to view more

X

5 Axis CNC Router Machine Price And Quantity

- 5000000.0 INR/Unit

- 1 Unit

5 Axis CNC Router Machine Product Specifications

- 440 Volt (v)

- 5 Axis CNC Router Machine

- Electric

- Other

- 6000x5000x2500 Millimeter (mm)

- Yes

- 18000 RPM

- Industrial

- 1 Year

- Low Energy Consumption

- 6000 Kilograms (kg)

- No

5 Axis CNC Router Machine Trade Information

- 10 Unit Per Month

- 60 Days

Product Description

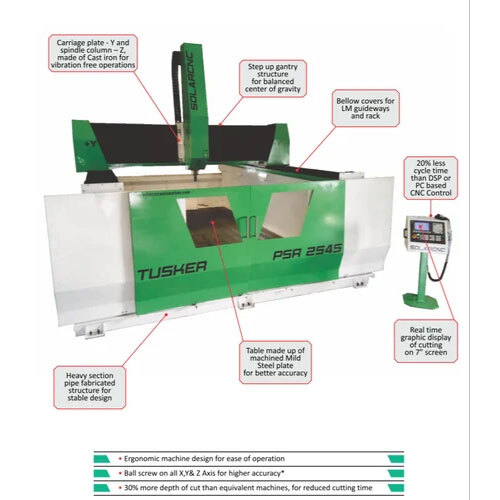

A 5-Axis CNC router is a computer-controlled cutting machine that moves the cutting tool or workpiece along five axes three linear (X, Y, Z) and two rotational axes (A and B) allowing the tool to reach almost any angle for complex 3D machining.

Core Components (what it contains)

-

Rigid machine frame for stability

-

Spindle with tool holder for cutting

-

Servo motors & drives to control all five axes

-

Linear guides & ball screws for precise movement

-

CNC control system to read G-code and coordinate motion

-

Workholding system (table, vices, fixtures) to secure parts

-

Feedback sensors for accuracy and calibration AccTek Group

Key Benefits

-

Machine complex shapes & surfaces in one setup. customproc.com

-

Improved precision and surface finish with fewer repositionings. BuyCNC

-

Higher productivity and less human error. BuyCNC

-

Versatile for wood, plastics, composites, and some metals. AccTek Group

Main Uses

Ideal for 3D carving, mold making, aerospace parts, automotive components, furniture, sculptures, and prototype machining where complex geometries and multi-surface machining are required.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free