- Home Page

- Company Profile

-

Our Products

- CNC Router And Wood Carving Machine

- CNC Milling Machine

- CNC Plasma Cutting Machine

- Plasma Cutting Machine

- Plasma Cutting CNC

- CNC Plasma Cutting Machine

- CNC Profile Cutting Machine

- CNC Gantry Type Plasma Cutting Machine

- Flash Cut CNC Oxy Fule and Plasma Cutting Machine

- Gantry CNC Plasma Flame Cutting Machine

- CNC Plasma Flame Cutting

- Portable Cnc Plasma Cutting Machine

- Table Top CNC Plasma Cutting Machine

- Portable Oxyfuel Cutting Machine

- Portable Cnc Flame Plasma Cutting Machine

- CNC Engraving Machine

- CNC Trainer Machines

- Special Purpose Machines

- CNC Lathe Machines

- Stone Engraving Machine

- Vertical Roll Storage Carousel

- Welding Robot

- CNC Machines

- CNC Router Machines

- Cnc Metal Engraving Machine

- 5 Axis CNC Router Machine

- CNC 3 Axis Stepper Router Machine

- CNC Router Machine SR-E 2614

- Double Spindle CNC Router Machine

- Double Head Stone CNC Router

- Wood Pattern Making Cnc Router Machine

- Industrial CNC Engraving Machine

- Robot Welding Machines

- CNC 3 Axis Servo Router Machine

- 3 Axis CNC Router Machine manufacturer in Gujarat

- CNC Pattern Router Machine

- Welding Fixtures

- Contact Us

CNC Plasma Cutting Machine

1050000 INR/Unit

Product Details:

- Product Type CNC Plasma Cutting Machine

- General Use CNC Cutting

- Material Stainless Steel

- Type Horizontal

- Computerized Yes

- Automatic Yes

- PLC Control Yes

- Click to view more

X

CNC Plasma Cutting Machine Price And Quantity

- 1 Unit

- 1050000 INR/Unit

CNC Plasma Cutting Machine Product Specifications

- Horizontal

- CNC Cutting

- Electric

- Stainless Steel

- Yes

- Low Energy Consumption, High Speed, High Precision

- CNC Plasma Cutting Machine

- Yes

- Yes

CNC Plasma Cutting Machine Trade Information

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID)

- 2-4 Week

- Asia

- All India

Product Description

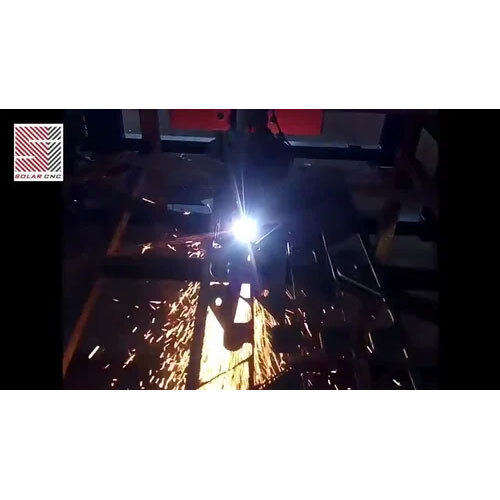

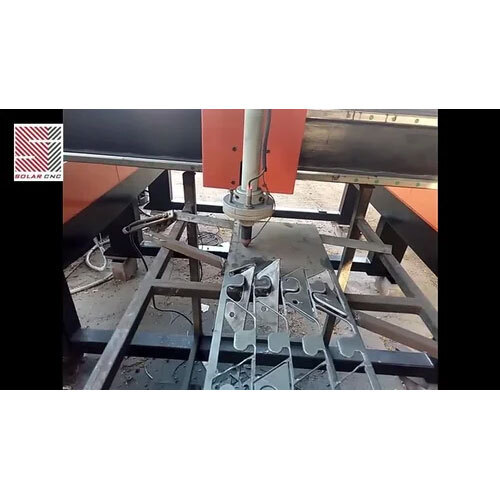

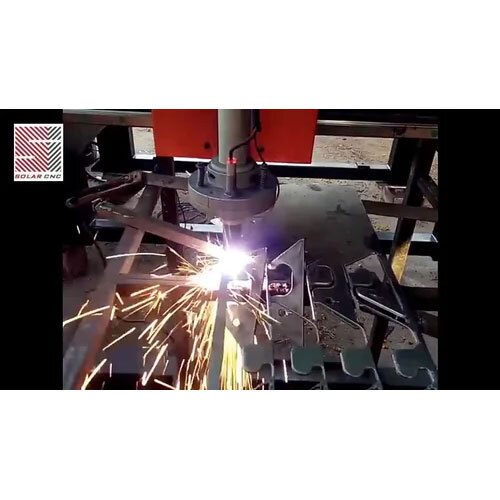

A CNC plasma cutting machine is a type of computer-controlled cutting machine that uses a plasma torch to cut through materials such as steel, aluminum, and other metals. The plasma torch works by creating a high-velocity jet of ionized gas (plasma) that heats and melts the material being cut, while a stream of compressed air or gas blows away the molten metal to create the cut.

The CNC (Computer Numerical Control) system allows for precise and accurate control over the cutting process, with the operator inputting the cutting parameters into the machine's computer system. The machine then follows these instructions to cut the material into the desired shape or size.

CNC plasma cutter are used in a variety of industries, including metal fabrication, automotive manufacturing, and construction. They offer several advantages over other cutting methods, including faster cutting speeds, lower operating costs, and the ability to cut a wide range of materials and thicknesses.

Frequently Asked Questions:

Here are some frequently asked questions about CNC plasma cutting machines:

1. What materials can be cut with a CNC plasma cutter?

Ans: CNC plasma cutting machines can cut a wide range of materials, including steel, stainless steel, aluminum, copper, brass, and other metals.

2. What is the thickness range of materials that can be cut with a CNC plasma cutting machine?

Ans: The thickness range of materials that can be cut with a CNC plasma cutter varies depending on the power of the machine and the type of material being cut. However, most machines can cut materials up to 1 inch thick, and some high-power machines can cut materials up to 6 inches thick.

3. How accurate is a CNC plasma cutting machine?

Ans: It very accurate, with typical tolerances ranging from +/- 0.005 inches to +/- 0.030 inches, depending on the machine's capabilities and the thickness of the material being cut.

4. What is the operating cost of a CNC plasma cutting machine?

Ans: The operating cost this machine includes the cost of the electricity used to power the machine, the cost of the consumables (such as plasma gas and electrode tips), and the cost of any maintenance and repairs that may be required. The exact operating cost will depend on the size and power of the machine, as well as the frequency and intensity of its use.

5. What are the advantages of using a CNC plasma cutting machine?

Ans: It offer several advantages over other cutting methods, including faster cutting speeds, lower operating costs, the ability to cut a wide range of materials and thicknesses, and the ability to create intricate and detailed designs. Additionally, because the machine is computer-controlled, it eliminates the need for manual cutting, which can be time-consuming and labor-intensive.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free