- Home Page

- Company Profile

-

Our Products

- CNC Router And Wood Carving Machine

- CNC Milling Machine

- CNC Plasma Cutting Machine

- Plasma Cutting Machine

- Plasma Cutting CNC

- CNC Plasma Cutting Machine

- CNC Profile Cutting Machine

- CNC Gantry Type Plasma Cutting Machine

- Flash Cut CNC Oxy Fule and Plasma Cutting Machine

- Gantry CNC Plasma Flame Cutting Machine

- CNC Plasma Flame Cutting

- Portable Cnc Plasma Cutting Machine

- Table Top CNC Plasma Cutting Machine

- Portable Oxyfuel Cutting Machine

- Portable Cnc Flame Plasma Cutting Machine

- CNC Engraving Machine

- CNC Trainer Machines

- Special Purpose Machines

- CNC Lathe Machines

- Stone Engraving Machine

- Vertical Roll Storage Carousel

- Welding Robot

- CNC Machines

- CNC Router Machines

- Cnc Metal Engraving Machine

- 5 Axis CNC Router Machine

- CNC 3 Axis Stepper Router Machine

- CNC Router Machine SR-E 2614

- Double Spindle CNC Router Machine

- Double Head Stone CNC Router

- Wood Pattern Making Cnc Router Machine

- Industrial CNC Engraving Machine

- Robot Welding Machines

- CNC 3 Axis Servo Router Machine

- 3 Axis CNC Router Machine manufacturer in Gujarat

- CNC Pattern Router Machine

- Welding Fixtures

- Contact Us

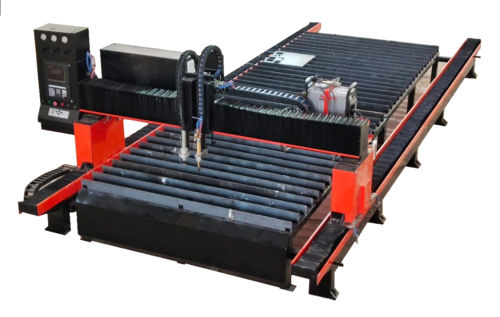

Flash Cut CNC Oxy Fule and Plasma Cutting Machine

1250000.00 INR/Piece

Product Details:

- Product Type FLASH CUT CNC OXY FUELA AND PLASMA CUTTING MACHINE

- General Use FOR CUTTING MS,SS & ALUMINUM

- Material Metal

- Weight (kg) 1500 Kilograms (kg)

- Computerized Yes

- Automatic Yes

- PLC Control No

- Click to view more

X

Flash Cut CNC Oxy Fule and Plasma Cutting Machine Price And Quantity

- 1 Piece

- 1250000.00 INR/Piece

Flash Cut CNC Oxy Fule and Plasma Cutting Machine Product Specifications

- FLASH CUT CNC OXY FUELA AND PLASMA CUTTING MACHINE

- 1 YEAR STANDARD

- High Speed, Low Energy Consumption, High Precision

- No

- 1500 Kilograms (kg)

- Metal

- High

- 7.5 X 3.2 X 1.5 Meter (m)

- 15 HP Horsepower (HP)

- AC Motor

- 2000 X 63000 (CUSTOMIZABLE)

- 3 AXIS

- Electric

- Yes

- Yes

- Black

- 440 Volt (v)

- FOR CUTTING MS,SS & ALUMINUM

- No

Flash Cut CNC Oxy Fule and Plasma Cutting Machine Trade Information

- NHAVASEVA MUMBAI

- Cash in Advance (CID), Cash Advance (CA), Cash on Delivery (COD), Cash Against Delivery (CAD), Cheque

- 2 Piece Per Month

- 4 Week

- Contact us for information regarding our sample policy

- Middle East, Africa, Australia, Asia

- All India

Product Description

A plasma cutting machine is a versatile tool used for precision cutting of various conductive materials, including metal, steel, and aluminum. It utilizes a high-temperature plasma jet to melt through the material, while compressed gas blows away the molten metal, resulting in clean and accurate cuts. Plasma cutting machines are commonly employed in industries such as metal fabrication, automotive, construction, and artistry, providing efficient and precise cutting solutions.

FAQ (Frequently Asked Questions):

Q: What is a plasma cutting machine?

A: A plasma cutting machine is a tool that uses a high-temperature plasma arc to cut through conductive materials. It combines an electrically conductive gas and a power source to generate a controlled plasma jet that melts the metal, allowing for precise cutting.

Q: How does a plasma cutting machine work?

A: A plasma cutting machine operates by creating an electrical circuit between the machine and the workpiece. An inert gas, such as nitrogen or argon, is passed through a small nozzle while an electric arc is formed between the nozzle and the workpiece. This electric arc ionizes the gas, turning it into plasma. The plasma reaches extremely high temperatures, melting the metal, and a high-velocity gas stream blows away the molten material, creating a clean cut.

Q: What are the advantages of using a plasma cutting machine?

A: Plasma cutting machines offer several advantages. They provide high cutting speeds, allowing for efficient production. The machines are versatile and can cut various thicknesses of metal. Plasma cutting produces minimal kerf width, resulting in less material wastage. It also creates clean cuts with minimal distortion and provides excellent cutting precision, especially in intricate designs and shapes.

Q: What types of materials can be cut with a plasma cutting machine?

A: Plasma cutting machines are primarily used to cut conductive materials, including mild steel, stainless steel, aluminum, copper, and brass. The thickness of the material that can be cut depends on the power of the plasma cutting machine.

Q: Can a plasma cutting machine create complex shapes and designs?

A: Yes, plasma cutting machines can create complex shapes and designs. With their high precision and ability to follow programmed paths, these machines can cut intricate patterns, curves, holes, bevels, and even 3D shapes.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email