- Home Page

- Company Profile

-

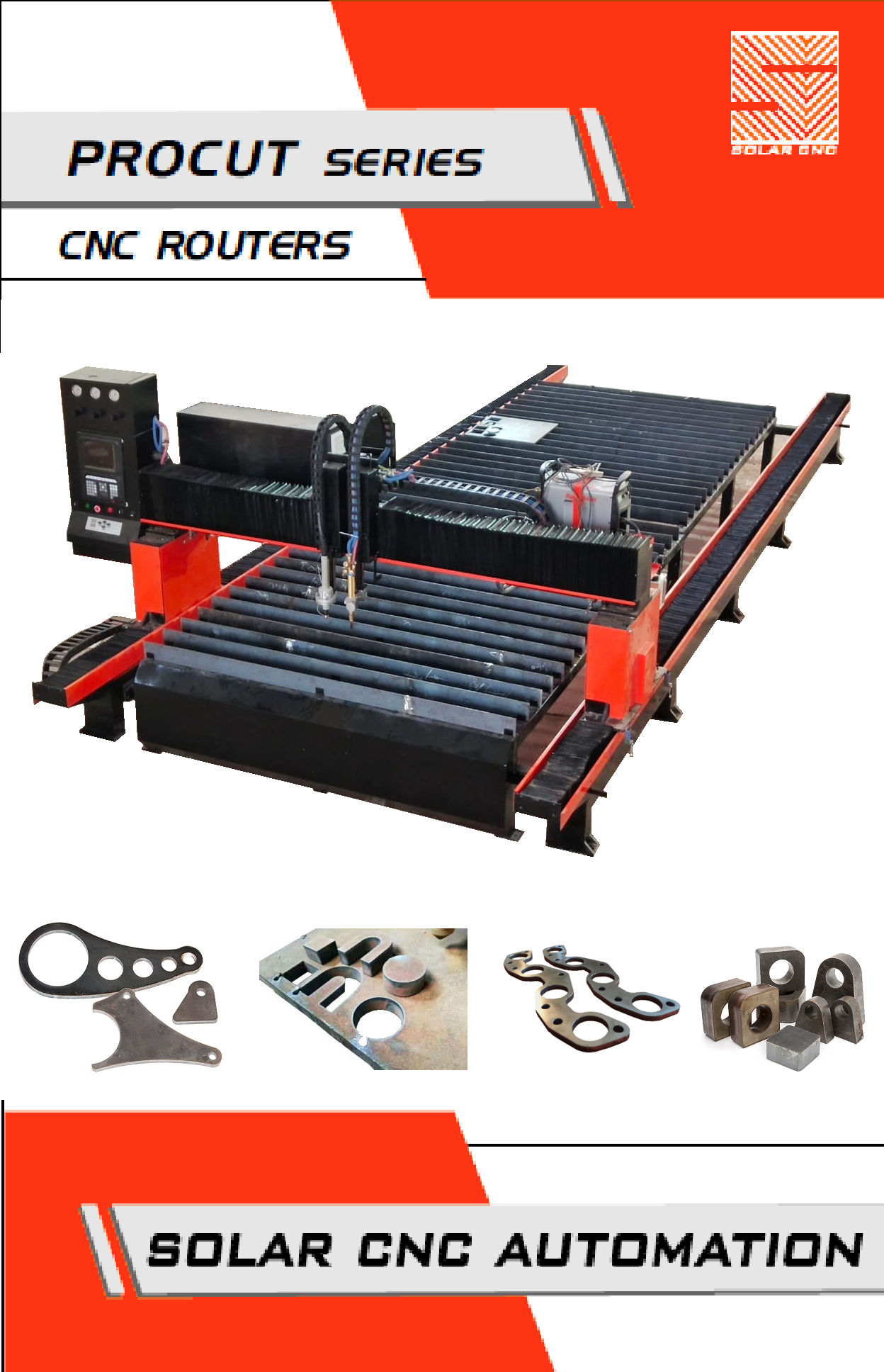

Our Products

- CNC Router And Wood Carving Machine

- CNC Milling Machine

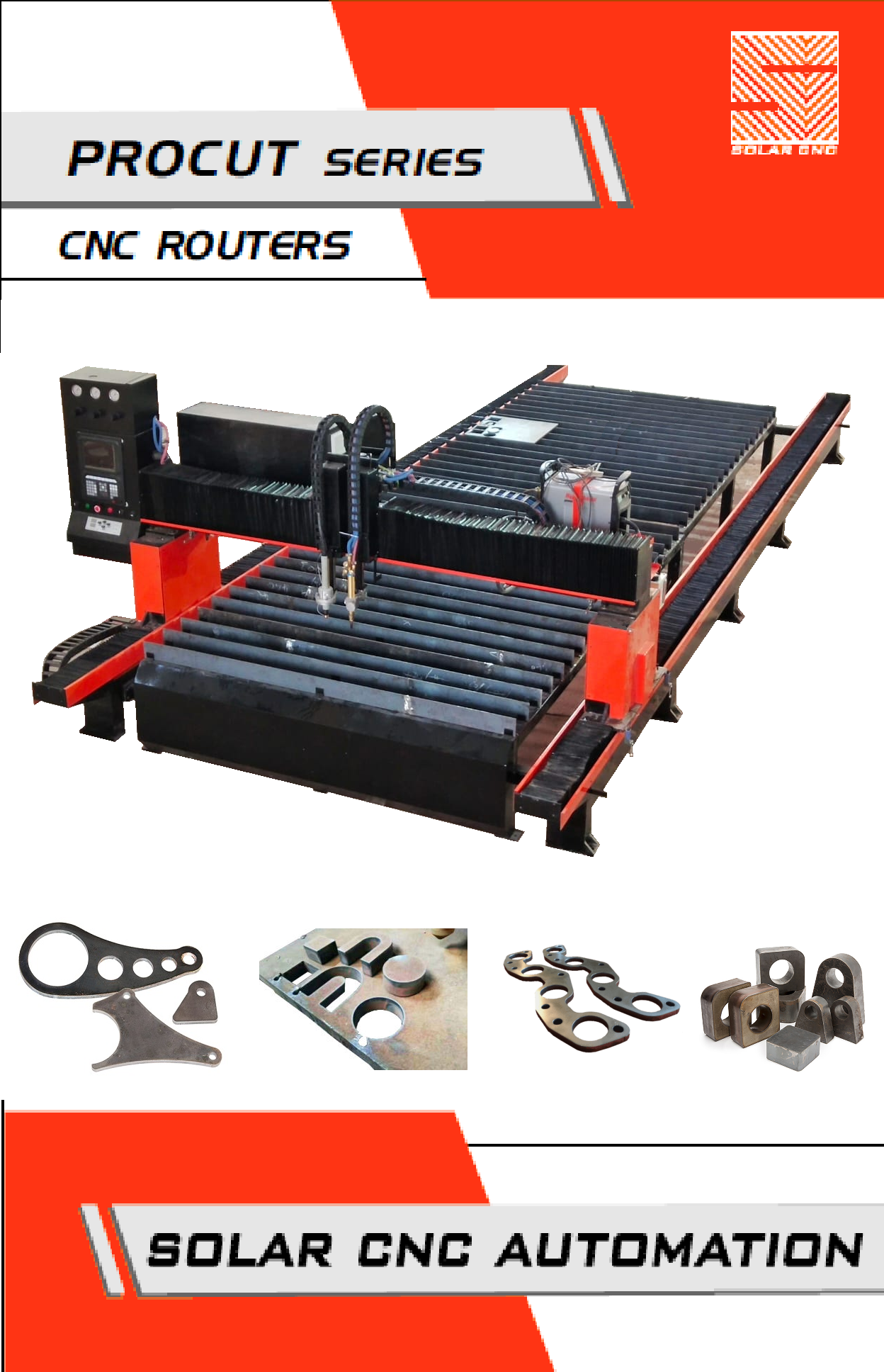

- CNC Plasma Cutting Machine

- Plasma Cutting Machine

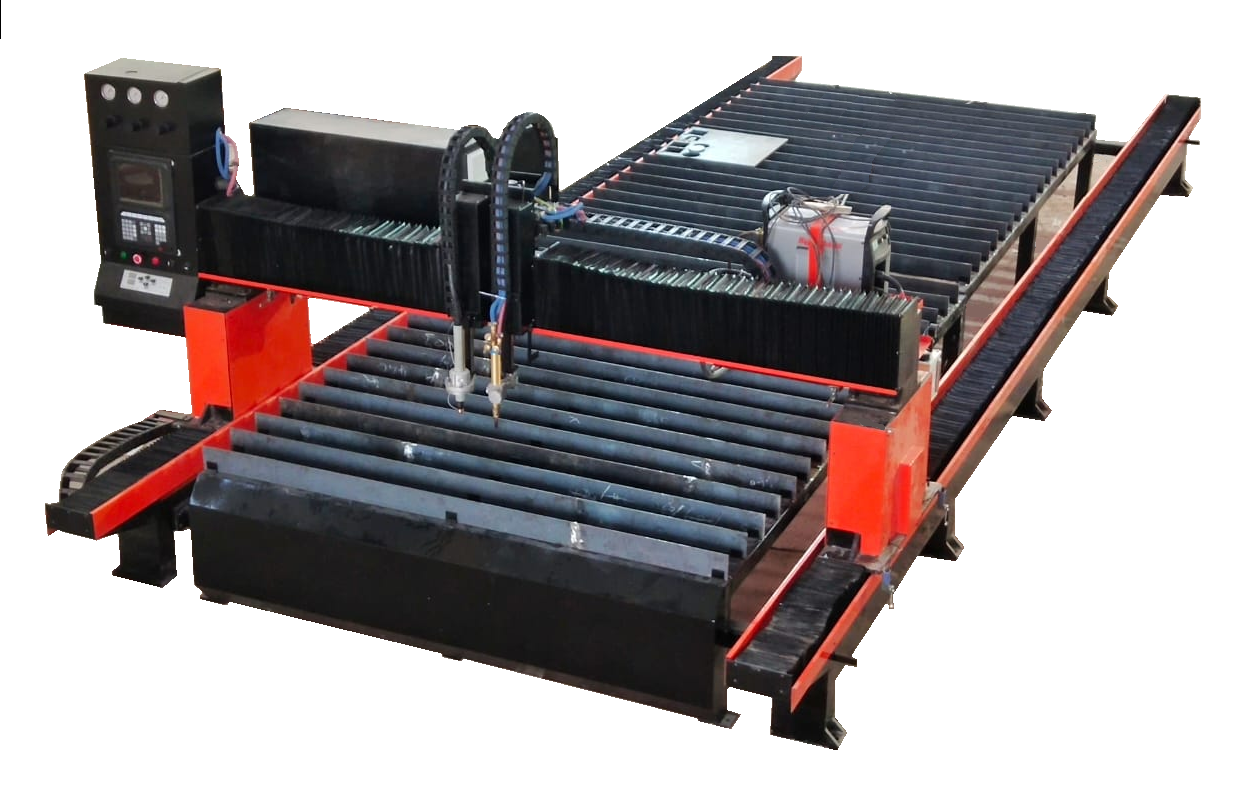

- Plasma Cutting CNC

- CNC Plasma Cutting Machine

- CNC Profile Cutting Machine

- CNC Gantry Type Plasma Cutting Machine

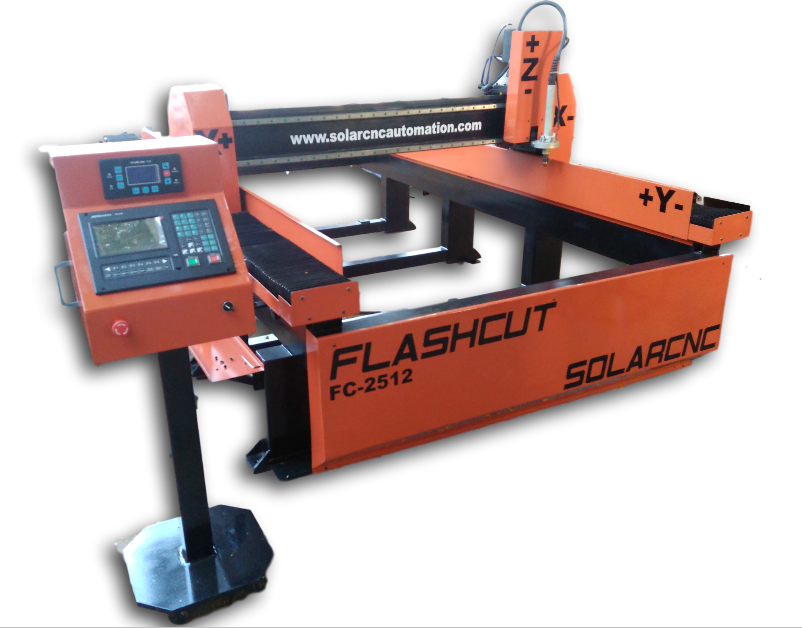

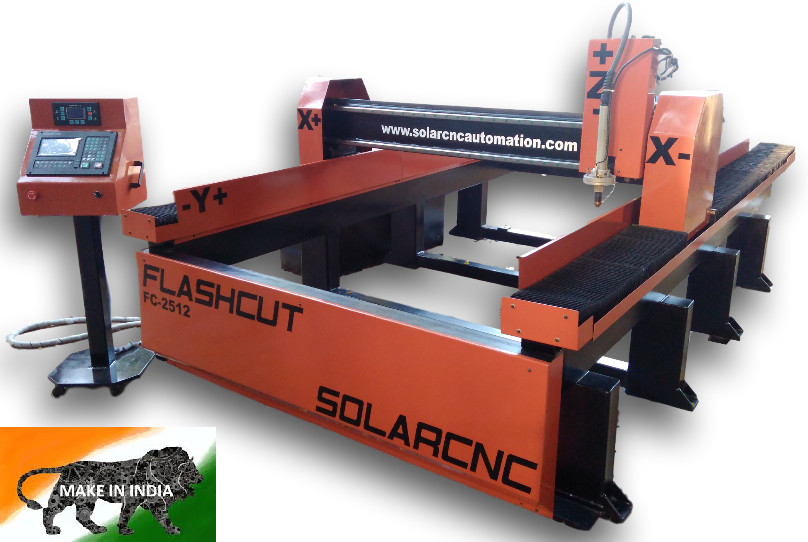

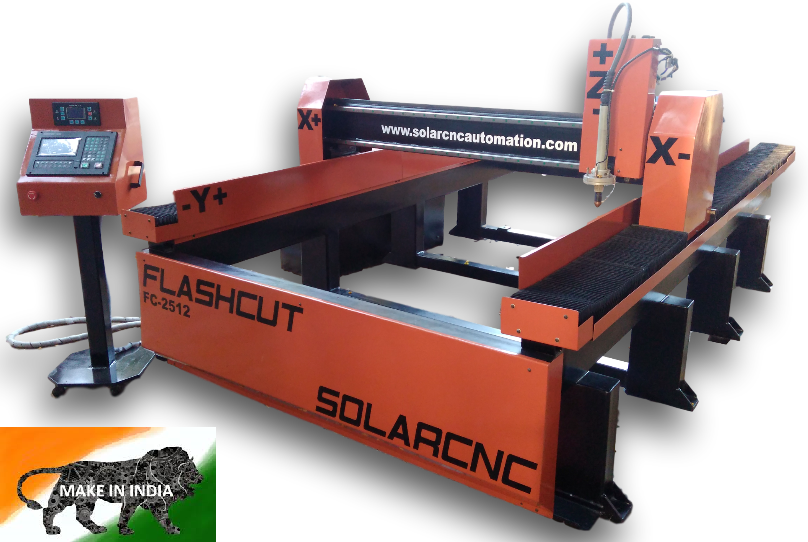

- Flash Cut CNC Oxy Fule and Plasma Cutting Machine

- Gantry CNC Plasma Flame Cutting Machine

- CNC Plasma Flame Cutting

- Portable Cnc Plasma Cutting Machine

- Table Top CNC Plasma Cutting Machine

- Portable Oxyfuel Cutting Machine

- Portable Cnc Flame Plasma Cutting Machine

- CNC Engraving Machine

- CNC Trainer Machines

- Special Purpose Machines

- CNC Lathe Machines

- Stone Engraving Machine

- Vertical Roll Storage Carousel

- Welding Robot

- CNC Machines

- CNC Router Machines

- Cnc Metal Engraving Machine

- 5 Axis CNC Router Machine

- CNC 3 Axis Stepper Router Machine

- CNC Router Machine SR-E 2614

- Double Spindle CNC Router Machine

- Double Head Stone CNC Router

- Wood Pattern Making Cnc Router Machine

- Industrial CNC Engraving Machine

- Robot Welding Machines

- CNC 3 Axis Servo Router Machine

- 3 Axis CNC Router Machine manufacturer in Gujarat

- CNC Pattern Router Machine

- Welding Fixtures

- Contact Us

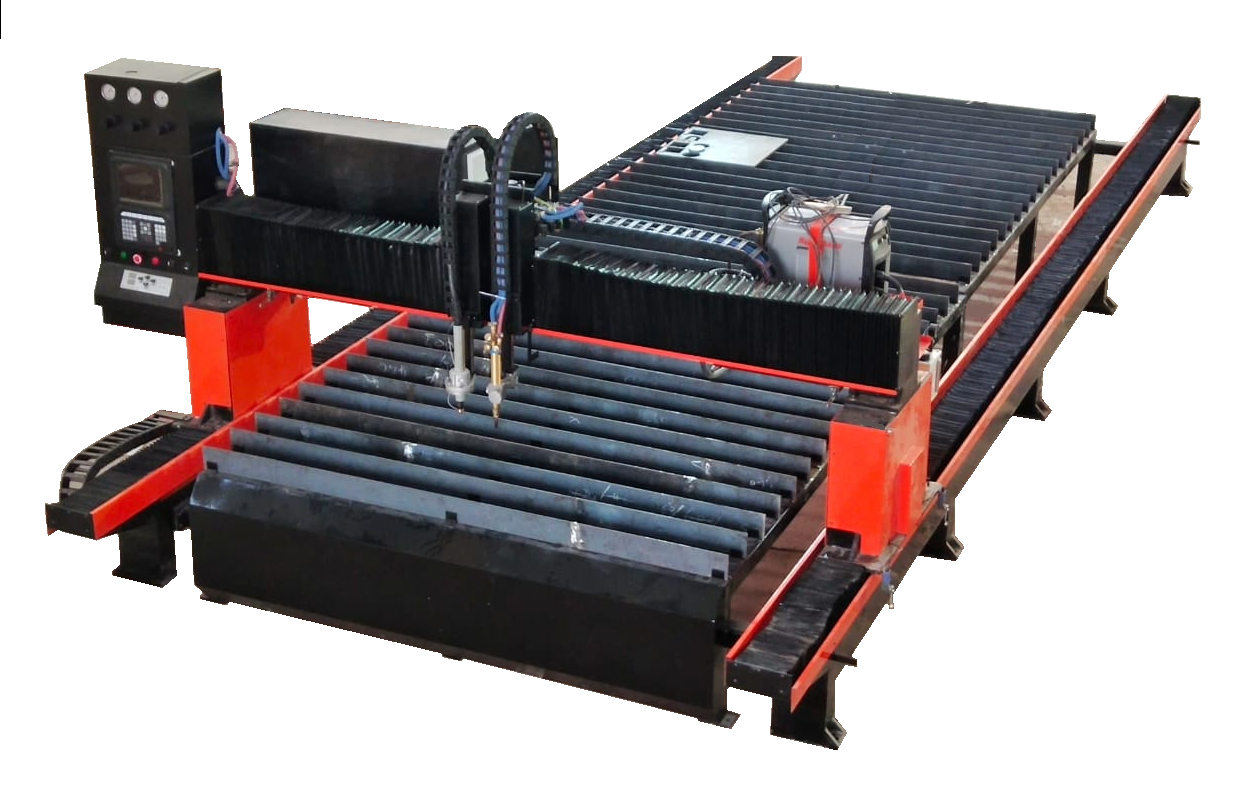

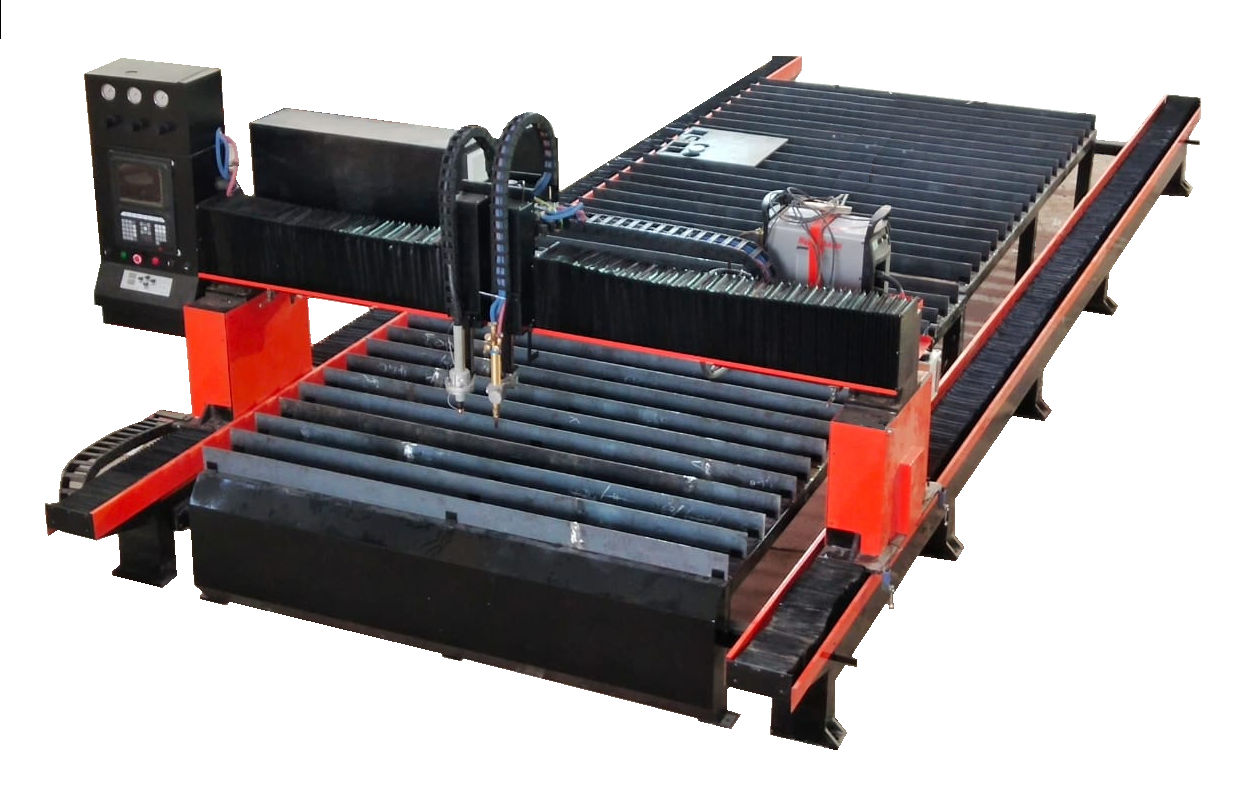

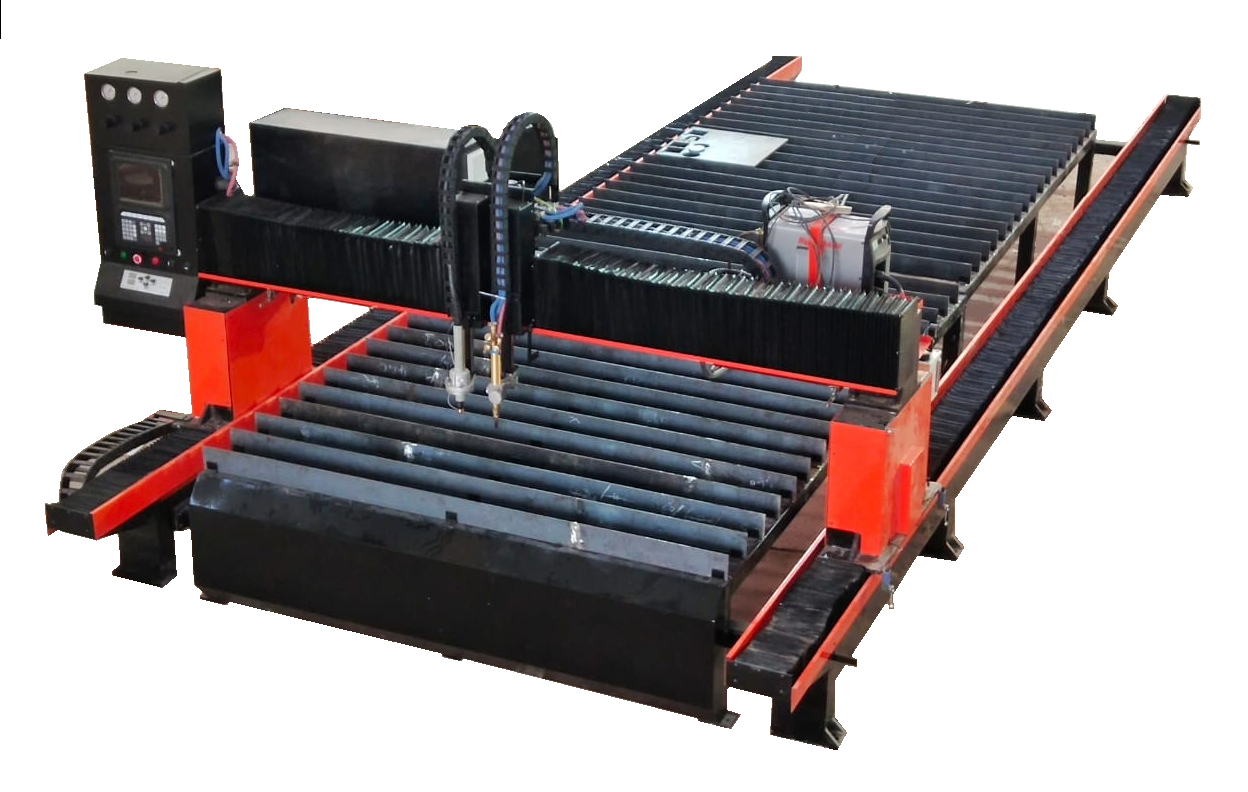

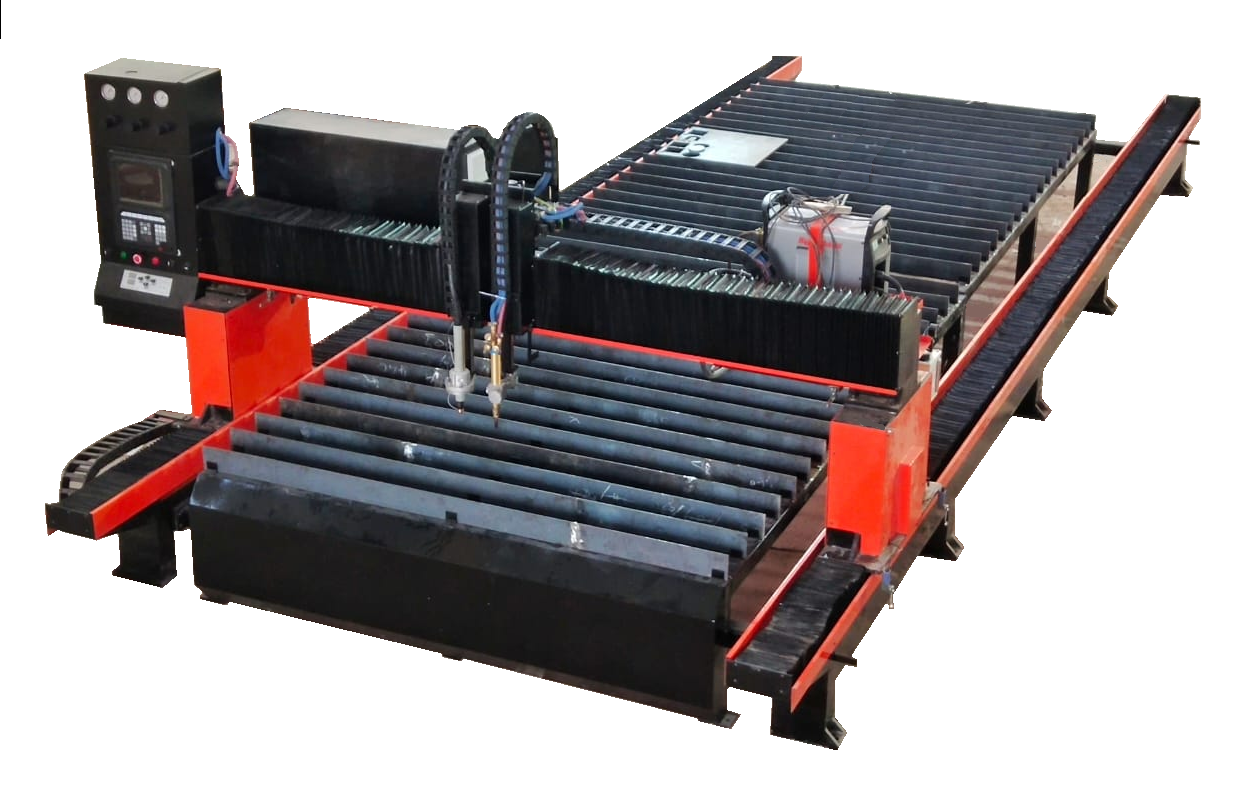

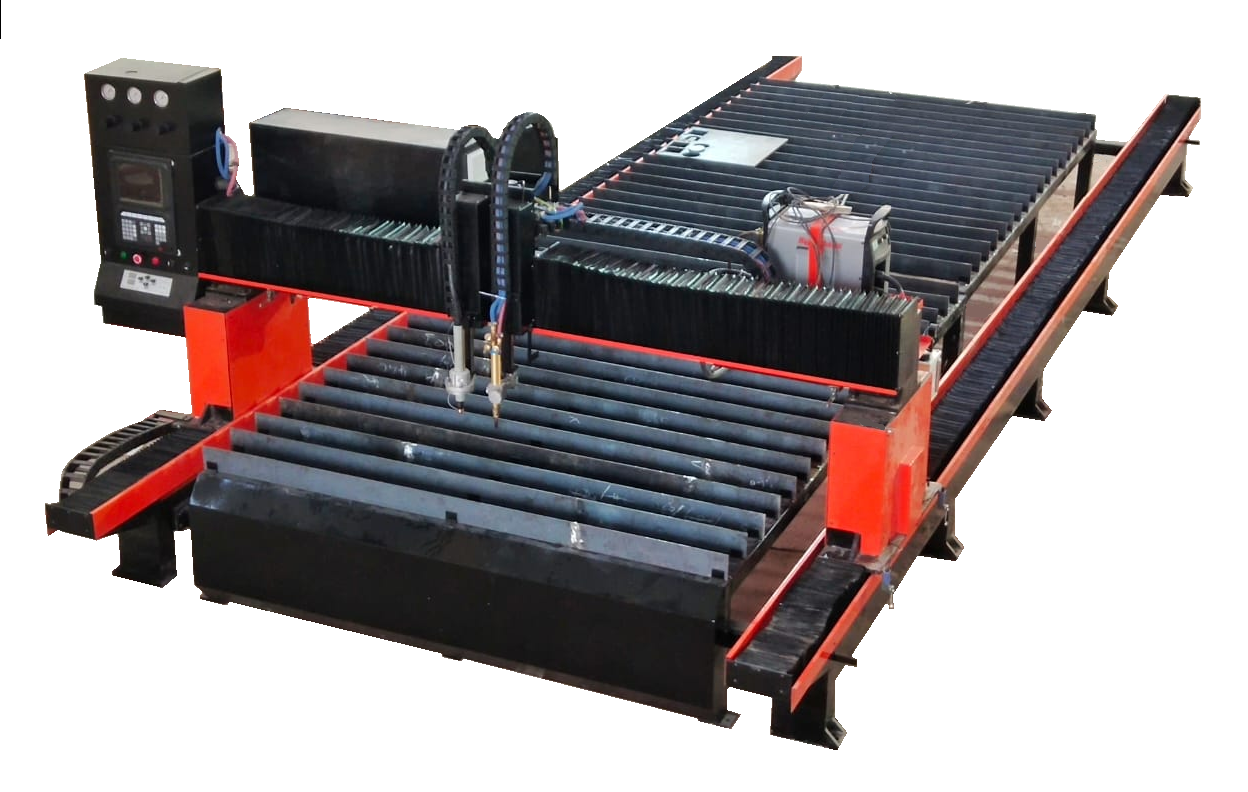

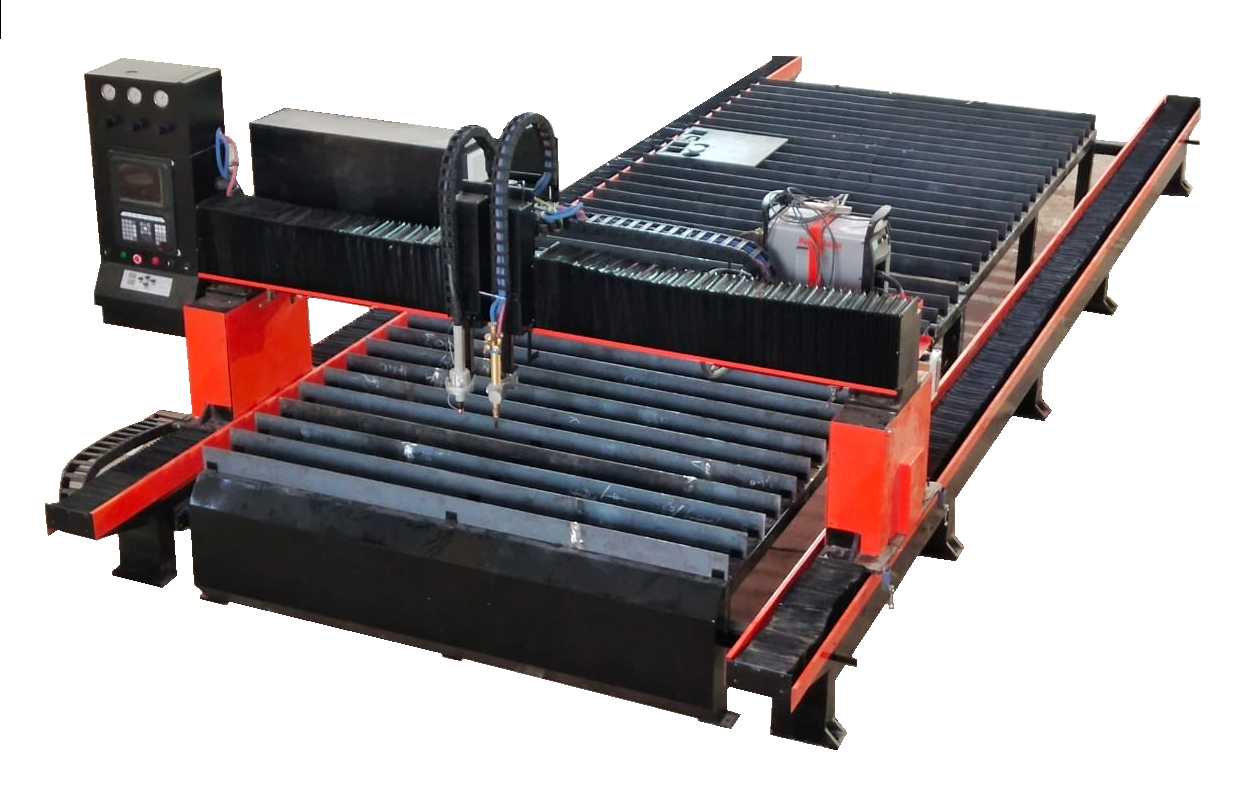

Plasma Cutting CNC

880000.00 INR/Unit

Product Details:

- Product Type Plasma Cutting CNC

- General Use Industry

- Material Mild Steel

- Computerized No

- Automatic Yes

- Voltage 220-440 Volt (v)

- Feature Low Energy Consumption

- Click to view more

X

Plasma Cutting CNC Price And Quantity

- 880000.00 INR/Unit

- 1 Unit

Plasma Cutting CNC Product Specifications

- Low Energy Consumption

- 1 year

- Plasma Cutting CNC

- Industry

- Other

- Yes

- Mild Steel

- No

- 220-440 Volt (v)

Plasma Cutting CNC Trade Information

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 1 Unit Per Week

- 45 Days

- Asia, Australia, Middle East, Africa

- All India

Product Description

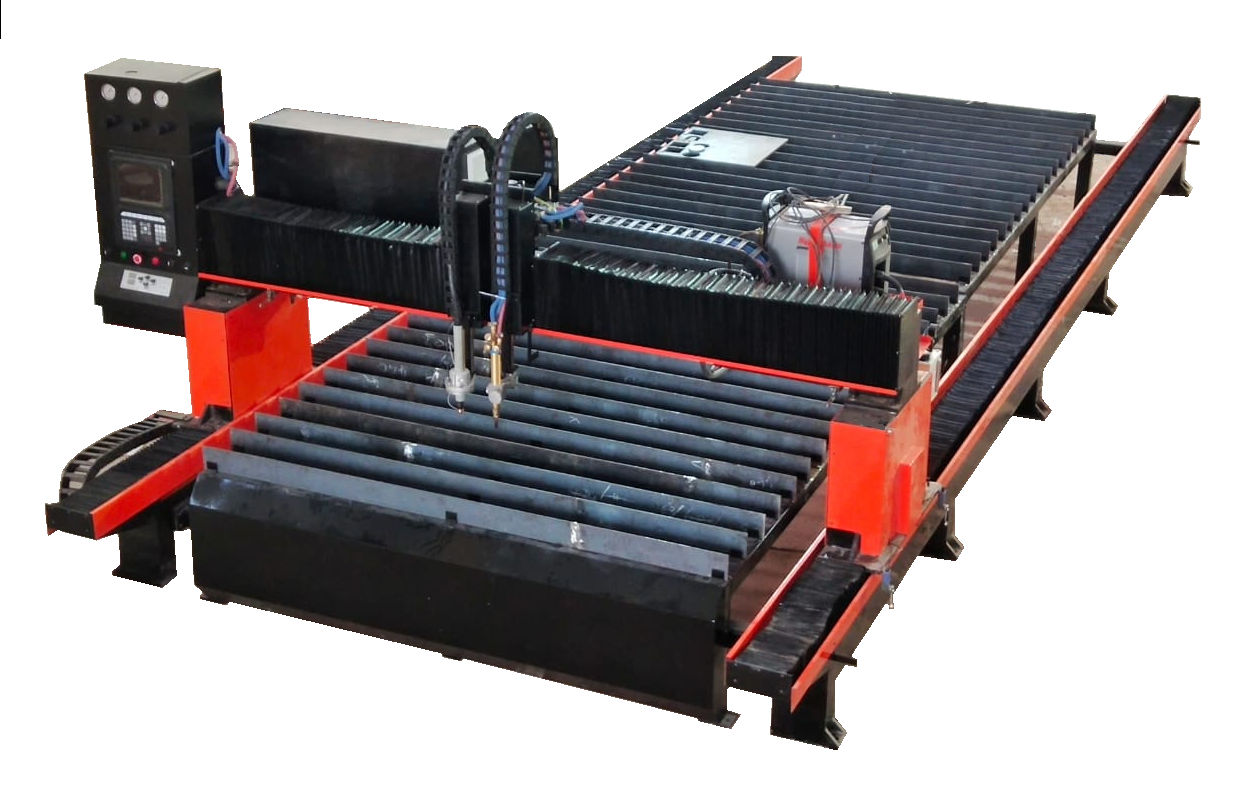

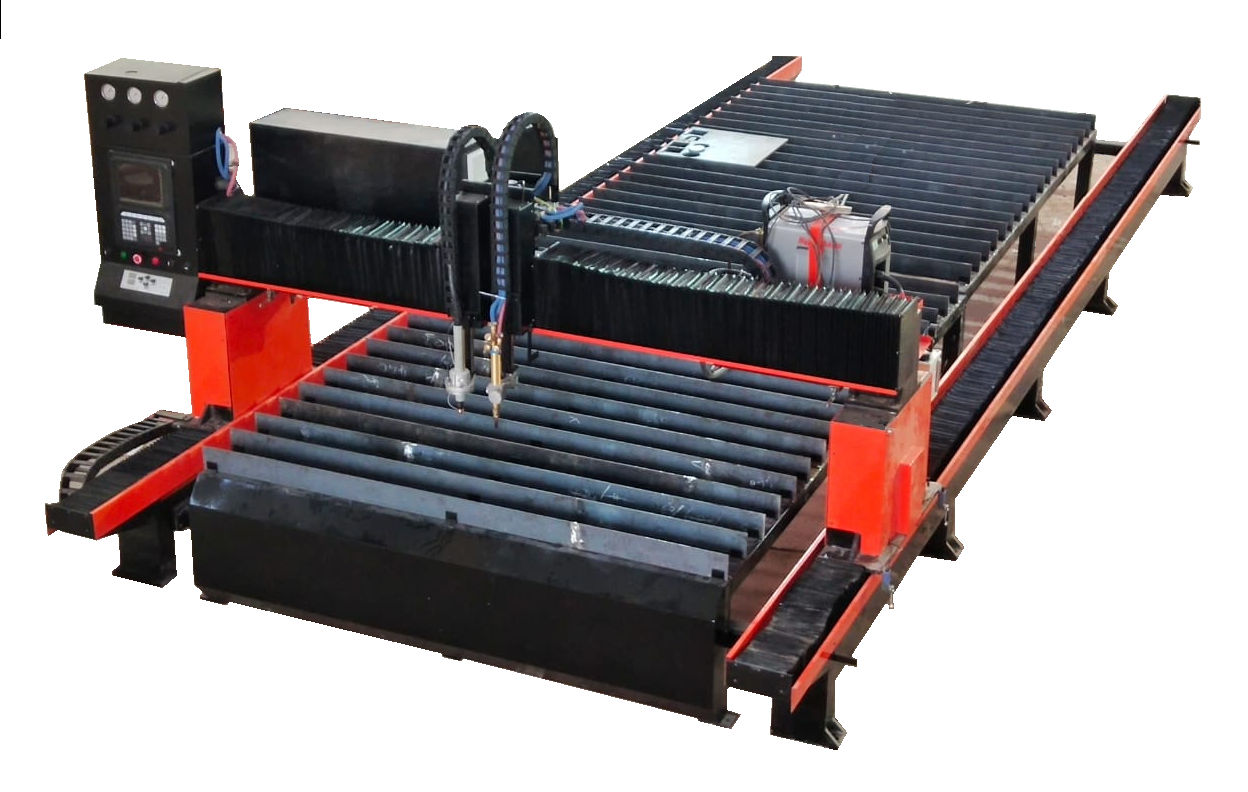

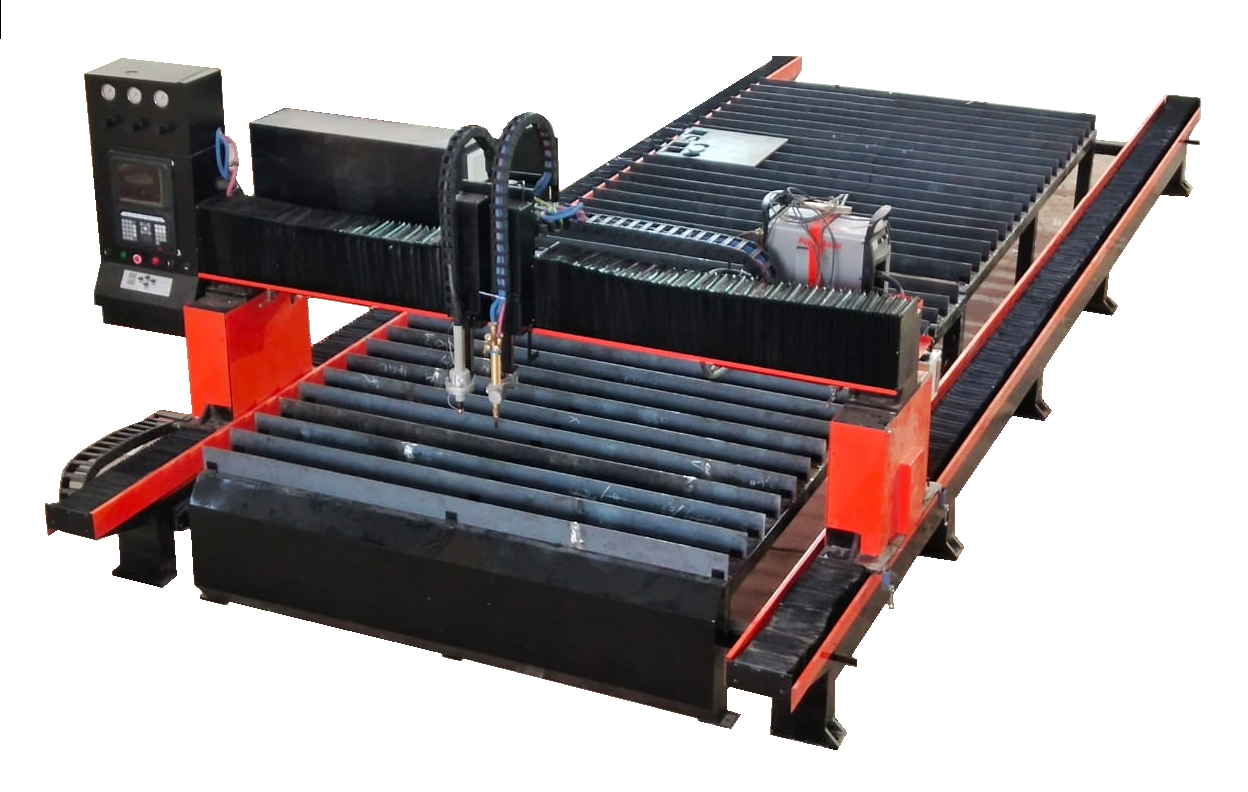

Plasma cutting CNC (Computer Numerical Control) refers to the integration of computerized controls with a plasma cutting machine. It combines the precision and versatility of CNC technology with the high-speed, efficient cutting capabilities of plasma to provide automated and accurate cutting solutions for various conductive materials. Plasma cutting CNC systems are widely used in industries such as metal fabrication, automotive, construction, and manufacturing, enabling efficient and precise cutting operations.

FAQ (Frequently Asked Questions):

Q: What is plasma cutting CNC?

A: Plasma cutting CNC refers to the use of computer numerical control technology to control and automate the operation of a plasma cutting machine. It combines the benefits of CNC precision and flexibility with the high-speed cutting capabilities of plasma, allowing for accurate and efficient cutting of conductive materials.

Q: How does plasma cutting CNC work?

A: Plasma cutting CNC systems work by using computer programs to control the movement of the plasma cutting machine's cutting head. The computer program, often generated with CAD/CAM software, specifies the cutting paths, speeds, and other cutting parameters. The CNC system translates these instructions into precise movements of the machine's motorized axes, guiding the plasma torch to cut the material accordingly.

Q: What are the advantages of using plasma cutting CNC?

A: Plasma cutting CNC offers several advantages. It provides exceptional cutting precision, allowing for the creation of intricate designs and shapes. The automation provided by CNC technology reduces manual labor, increases productivity, and ensures consistent and accurate cutting results. Plasma cutting CNC systems also offer versatility, enabling cutting of various thicknesses and types of conductive materials.

Q: What types of materials can be cut with plasma cutting CNC?

A: Plasma cutting CNC systems can cut a wide range of conductive materials, including mild steel, stainless steel, aluminum, copper, brass, and other metals. The cutting capability depends on the power and specifications of the plasma cutting machine.

Q: Can plasma cutting CNC create complex shapes and designs?

A: Yes, plasma cutting CNC systems excel at creating complex shapes and designs. With the precision and flexibility of CNC control, these systems can accurately cut intricate patterns, curves, holes, bevels, and even three-dimensional shapes.

Q: Is programming knowledge required to operate plasma cutting CNC?

A: Operating plasma cutting CNC systems generally requires programming knowledge. Users need to create or obtain CNC programs that specify the cutting paths, speeds, and cutting parameters. However, user-friendly software interfaces and pre-designed templates are available to simplify the programming process for users with varying levels of programming expertise.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email