- Home Page

- Company Profile

-

Our Products

- CNC Router And Wood Carving Machine

- CNC Milling Machine

- CNC Plasma Cutting Machine

- Plasma Cutting Machine

- Plasma Cutting CNC

- CNC Plasma Cutting Machine

- CNC Profile Cutting Machine

- CNC Gantry Type Plasma Cutting Machine

- Flash Cut CNC Oxy Fule and Plasma Cutting Machine

- Gantry CNC Plasma Flame Cutting Machine

- CNC Plasma Flame Cutting

- Portable Cnc Plasma Cutting Machine

- Table Top CNC Plasma Cutting Machine

- Portable Oxyfuel Cutting Machine

- Portable Cnc Flame Plasma Cutting Machine

- CNC Engraving Machine

- CNC Trainer Machines

- Special Purpose Machines

- CNC Lathe Machines

- Stone Engraving Machine

- Vertical Roll Storage Carousel

- Welding Robot

- CNC Machines

- CNC Router Machines

- Cnc Metal Engraving Machine

- 5 Axis CNC Router Machine

- CNC 3 Axis Stepper Router Machine

- CNC Router Machine SR-E 2614

- Double Spindle CNC Router Machine

- Double Head Stone CNC Router

- Wood Pattern Making Cnc Router Machine

- Industrial CNC Engraving Machine

- Robot Welding Machines

- CNC 3 Axis Servo Router Machine

- 3 Axis CNC Router Machine manufacturer in Gujarat

- CNC Pattern Router Machine

- Welding Fixtures

- Contact Us

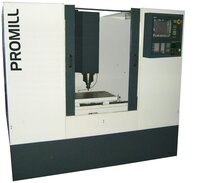

CNC Milling

1650000 INR/Unit

Product Details:

- Product Type CNC Milling Machine

- General Use Industry

- Material Metal

- Weight (kg) 2000 Kilograms (kg)

- Computerized Yes

- Automatic Yes

- PLC Control Yes

- Click to view more

X

CNC Milling Price And Quantity

- 1 Pair

- 1650000 INR/Unit

CNC Milling Product Specifications

- Yes

- 10,000 mm/m

- Yes

- Industry

- 800*500

- Yes

- CNC Milling Machine

- Metal

- Gray

- High

- Yes

- AC Motor

- 415 Volt (v)

- 1 year

- 415 Kilowatt (kW)

- Electric

- 2000 Kilograms (kg)

CNC Milling Trade Information

- Cash in Advance (CID), Letter of Credit (L/C)

- 1 Pair Per Week

- 15 Days

Product Description

CNC milling is a precision machining process that involves using computer-controlled machines to remove material from a workpiece to create complex shapes and features. It is widely used in manufacturing and prototyping to produce parts for various industries, including aerospace, automotive, electronics, and more. CNC milling machines utilize rotating cutting tools to remove material from the workpiece, following precise instructions programmed into the computer, resulting in highly accurate and repeatable components.

Frequently Asked Questions (FAQ):

Q: What does CNC stand for in CNC milling?

A: CNC stands for Computer Numerical Control. CNC milling machines are controlled by computer programs that generate specific toolpaths and instructions for cutting the workpiece.

Q: How does CNC milling work?

A: In CNC milling, the operator creates a digital design or model of the part to be produced using computer-aided design (CAD) software. This design is then translated into machine instructions (G-codes and M-codes) that guide the CNC milling machine to move the cutting tools in precise patterns to remove material from the workpiece and create the desired shape.

Q: What types of materials can be CNC milled?

A: CNC milling is versatile and can be used with a wide range of materials, including metals (such as aluminum, steel, and titanium), plastics, composites, and even certain types of wood.

Q: What are the advantages of CNC milling?

A: CNC milling offers several advantages, including high precision, repeatability, and efficiency. It can produce complex parts with tight tolerances, reduces the need for manual labor, and allows for rapid prototyping and mass production.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email